Heat treating processes involve heating and cooling metal to imbue the material with more advantageous characteristics for its intended application. Depending on the metal itself and the specific heat treatment used, heat treatments can improve the metal’s durability, physical damage resistance, corrosion resistance, and more. These processes are particularly important for any component that faces harsh working conditions, such as aircraft parts, automobile components, industrial tools, and heavy equipment parts.

At OPM Manufacturing, we have years of experience pairing metal stock and components with the appropriate heat treating processes to improve specific properties that will enhance performance. We provide multiple heat treating services to improve the long-term quality and performance of metal parts.

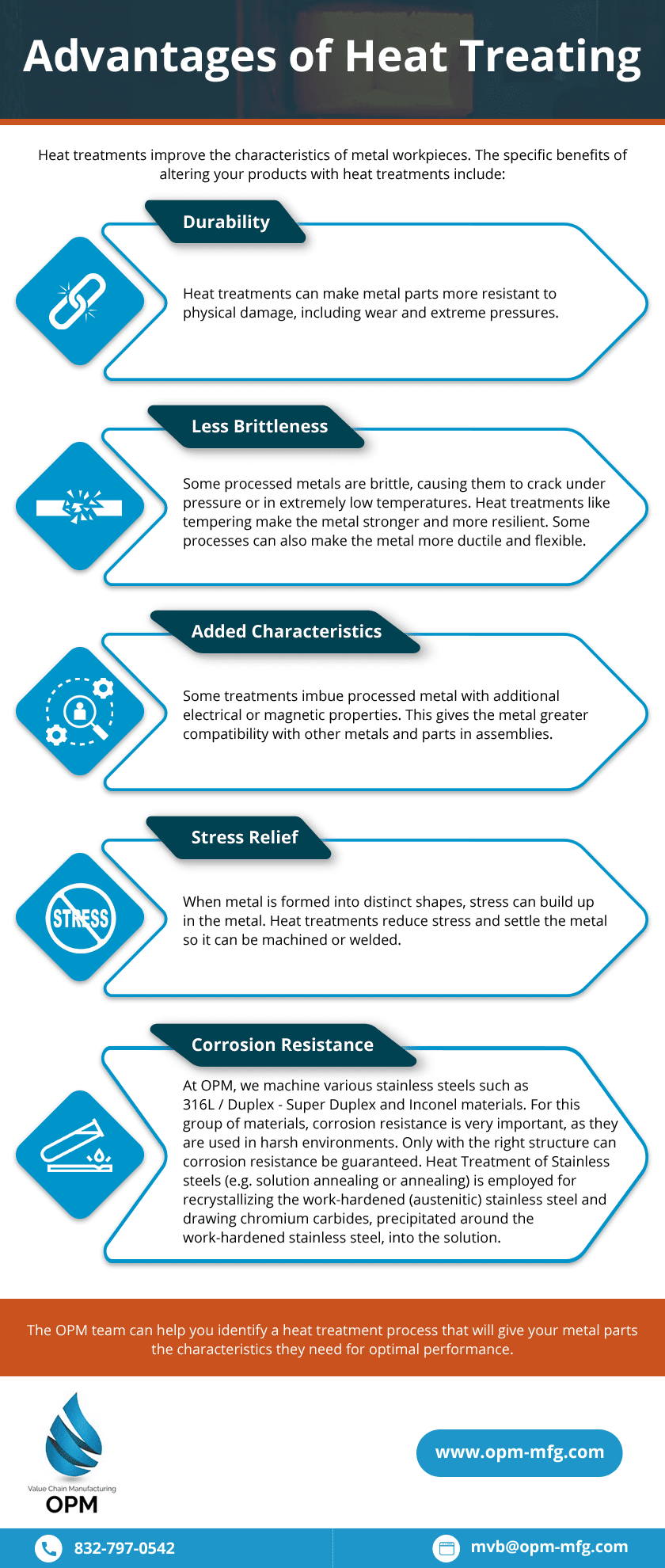

Advantages of Heat Treating Services

Heat treatments improve the characteristics of metal workpieces. The specific benefits of altering your products with heat treatments include:

Durability. Heat treatments can make metal parts more resistant to physical damage, including wear and extreme pressures.

- Less brittleness. Some processed metals are brittle, causing them to crack under pressure or in extremely low temperatures. Heat treatments like tempering make the metal stronger and more resilient. Some processes can also make the metal more ductile and flexible.

- Added characteristics. Some treatments imbue processed metal with additional electrical or magnetic properties. This gives the metal greater compatibility with other metals and parts in assemblies.

- Less stress. When metal is formed into distinct shapes, stress can build up in the metal. Heat treatments reduce stress and settle the metal so it can be machined or welded.

The OPM team can help you identify a heat treatment process that will give your metal parts the characteristics they need for optimal performance.

Our Heat Treating Services

At OPM Manufacturing, we specialize in heat treatments that improve the strength, composition, and other physical characteristics of your metal components. Our popular heat treating services include:

- Stainless steel solution treatment. OPM offers numerous methods for heat treating steel, depending on the specific alloy and its intended use case. Annealing, hardening, and stress relieving are often used to improve physical properties such as corrosion resistance or ductility. Stainless steel solution treatments may be applied to make the metal more malleable during fabrication, to elevate the toughness and plasticity of cast parts, or to improve the ability of parts to handle stresses or abrasive elements in their end applications.

- Carbon steel quenching. Quenching heats up the steel to a high temperature, then douses it in oil to quickly cool it and facilitate hardening. The exact temperature and other details may vary depending on the specific carbon steel alloy. Quenched steel workpieces will then go through additional stress relief, aging, or tempering processes until they reach their desired final properties.

- Pickling. Pickling is a chemical treatment process used to remove high-temperature scaling and low-chromium layers from stainless steel surfaces. This process is common for removing the low-chromium, colored oxide layer that forms on surfaces after welding or heat treating. This layer provides minimal corrosion resistance, so it must be removed to expose a fresh stainless steel surface with a standard chromium content.

- Passivation. The passivation process treats a stainless steel surface with an acid solution to eliminate contaminants and form a thin protective layer. This layer helps to remove microscopic damage that occurs on surfaces through fabrication processes such as machining or grinding.

- Quench Polish Quench (QPQ). QPQ—also known by brand names like Melonite, Tenifer, or Tufftride— refers to a specialized nitrocarburizing case hardening process used with certain steel and other iron alloy parts. QPQ gets its name from its three-step method: nitrocarburizing heats the part to a high temperature and quenches it to cool it off, then the cooled part is polished, then it is heated and quenched again. Parts that undergo QPQ feature better fatigue strength, lubricity, corrosion resistance, and wear resistance.

- Nitriding. Nitriding hardens steel surfaces by adding nitrogen. This may be achieved using an ion, plasma, or gaseous ammonia process that diffuses nitrogen into the surface.

- Carburizing. This heat treating process creates wear resistance surfaces on low-carbon and high-alloy steel parts, making the materials suitable for high-wear moving components such as gears and bearings. The core of the material maintains its strength and toughness, while the surface layer offers superior wear resistance.

Choose OPM Manufacturing for Heat Treating Services

The right heat treatment will improve the strength, resiliency, and performance of your metal components. Contact us today to see how we can help.