What is Machining?

“Machining” is a broad term that refers to certain subtractive manufacturing processes that shape a workpiece. During machining, a cutting tool removes material from a blank until the workpiece has the desired shape, size, and surface finish. In most cases, a program guides the cutting tool via computer numerical control (CNC), making the process fast, accurate, and highly repeatable.

Different machining techniques achieve different effects, and products usually undergo multiple stages of machining before moving onto secondary services and hand finishing. In the early stages of fabrication, rough machining helps cut raw material into usable workpieces of approximately the right size. Then, toward the end of fabrication, finishing processes refine a component’s shape and surface finish to align with specifications.

Manufacturers can devise a sequence of machining steps to form components of all shapes and sizes. However, each machining process also contributes to residual stress in the metal. Heat treatments can help redistribute stress and eliminate distortions to create a more stable product. Because of this, most manufacturers perform stress relieving between stages of machining to prevent defects from appearing later.

At OPM Manufacturing, our skilled technicians use machining at every stage of the manufacturing process to achieve consistent, high-quality results with competitive turnaround times. Our machining services include rough machining, stress relieving, and final machining processes.

Rough Machining

Rough machining is the first step in many metal fabrication processes. Rough machining, or roughing, quickly strips unneeded material to create smaller workpieces. Removing excess metal facilitates the subsequent finishing processes, which are responsible for the final shape and surface characteristics.

Since the goal of rough machining is to quickly create manageable workpieces, manufacturers use low-precision tools like ripper cutters at high feed rates. This allows for rapid material removal at the expense of precision. If there is a great deal of excess material, manufacturers often use ripper blades to tear large portions of metal from the workpiece, leaving the edges to be smoothed later.

Rough machining is often followed by semi-roughing. Semi-roughing is a more targeted form of roughing in which a smooth blade slices the side of the workpiece to further reduce bulk. Used together, roughing and semi-roughing create an ideal workpiece for efficient finishing.

Stress Relieving

Although stress relieving is not itself a machining process, it is an important complement to machining as it reduces the likelihood that a machined component will deform or crack. Most manufacturers will relieve stress after roughing but before finishing.

The Stress Relieving Process

A controlled cycle of heating and cooling is sufficient to relieve stress in a metal. Steel should be heated to approximately 600° C and soaked for several hours (typically one hour per inch of thickness), although these parameters depend on the metal and alloy. Adding a protective gas to the furnace can prevent the metal surface from oxidizing during the process.

While the heat treatment itself is sufficient to redistribute stress and eliminate distortions, it is important to allow the metal to cool slowly, as rapid or uneven cooling can introduce their own stress patterns. Once cooled, the components are ready for finishing

Benefits of Stress Relieving

The primary benefit of stress relieving is that it protects a component’s dimensional stability. Machining naturally induces stress patterns in the metal, which release when exposed to pressure, creating a distortion or crack in the material. Stress relieving ensures that components can withstand use without becoming deformed or cracked.

Stress relieving also makes it easier for manufacturers to achieve precise tolerances during the finishing stages of fabrication. Residual stress can make it difficult or impossible to guarantee tight tolerances due to the risk of deformation, so stress relieving is especially critical for precision components.

Final Machining Process

Roughing and semi-roughing only loosely approximate the final component’s shape—additional machining is necessary to create a usable product. The final machining steps include semi-finishing, which brings the workpiece close to its final state, and finishing, which completes the design and refines the surface. These finishing processes have both practical and aesthetic goals, including the following:

- Creating features such as holes, curves, or slots

- Improve dimensional accuracy and tolerances

- Remove rough patches, machining marks, scales, and pits from the surface

- Prepare the workpiece for secondary services such as coating or painting

To achieve these aims, manufacturers use shallower cuts, smaller or sharper blades, and slower feed rates to maximize precision. The final machining process often combines multiple stages of machining with a series of increasingly precise cutting tools. The controlled pace, while slow, enables the excellent tolerances and repeatability that characterize CNC machining.

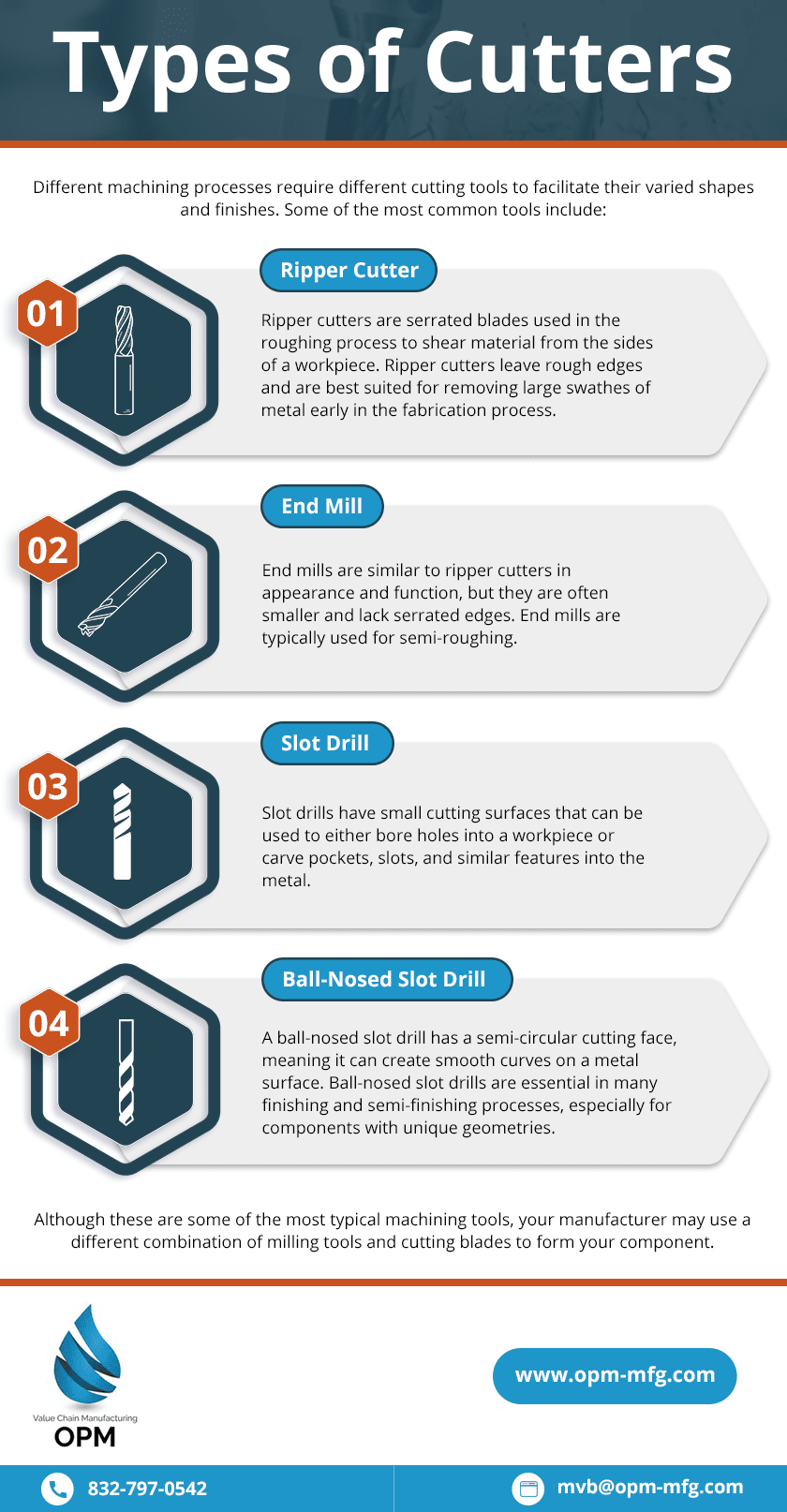

Types of Cutters

Different machining processes require different cutting tools to facilitate their varied shapes and finishes. Some of the most common tools include:

- Ripper Cutter. Ripper cutters are serrated blades used in the roughing process to shear material from the sides of a workpiece. Ripper cutters leave rough edges and are best suited for removing large swathes of metal early in the fabrication process.

- End Mill. End mills are similar to ripper cutters in appearance and function, but they are often smaller and lack serrated edges. End mills are typically used for semi-roughing.

- Slot Drill. Slot drills have small cutting surfaces that can be used to either bore holes into a workpiece or carve pockets, slots, and similar features into the metal.

- Ball-Nosed Slot Drill. A ball-nosed slot drill has a semi-circular cutting face, meaning it can create smooth curves on a metal surface. Ball-nosed slot drills are essential in many finishing and semi-finishing processes, especially for components with unique geometries.

Although these are some of the most typical machining tools, your manufacturer may use a different combination of milling tools and cutting blades to form your component.

Trusted Machining by OPM Manufacturing

OPM Manufacturing is a trusted provider of precision machined goods, including a diverse array of metal products. Our machining solutions include rough machining, stress relieving, and a full array of finishing techniques to suit any project.

By working with us, you benefit from our:

- Custom material capabilities. We can handle projects that require custom alloys and steels.

- Engineering and logistic support services. Our engineering team can recommend design changes and/or materials to improve manufacturability or reduce cost.

- Commitment to traceability. All of our products are individually serialized to ensure 100% material and staff traceability. You can trace any product back to the staff that worked on it at each station, from incoming inventory processing to product shipping.

To learn more about our capabilities or to get started on your next metal fabrication project, contact our team today.