Manufacturers frequently use wire electrical discharge machining (EDM) because of the benefits it offers especially when working with hard, conductive materials. The innovation of wire EDM allows for increased precision even for complex part designs. Here you’ll learn more about what wire EDM is, how it works, and its many applications.

What Is Wire EDM?

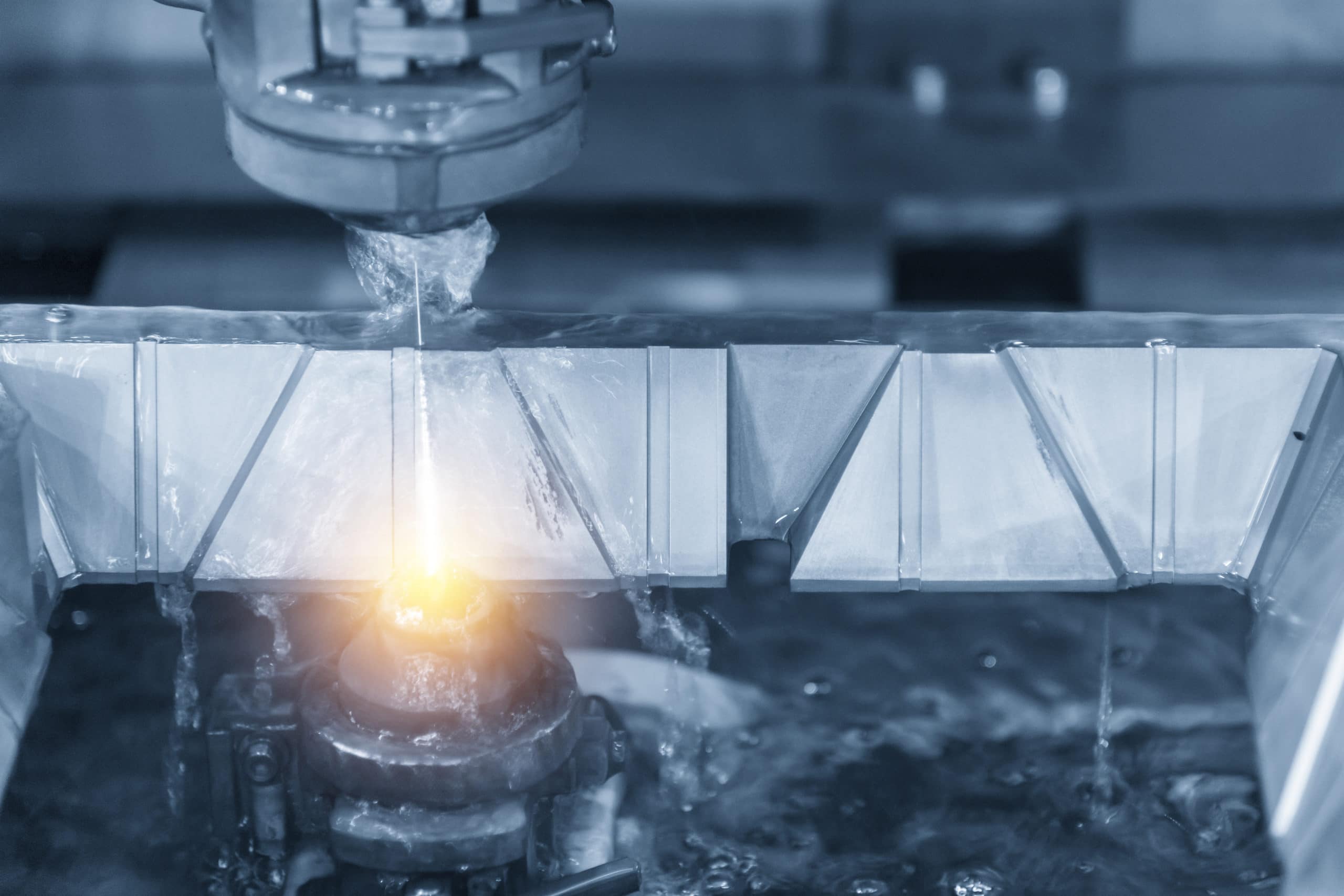

Wire EDM is an electrothermal production process that involves using focused electrical energy to generate heat to machine materials. The process uses a thin metal wire electrode to create electrical discharge between it and the workpiece. Deionized water conducts electricity and enables the electrode to cut through the metal while preventing corrosion. This method is also known as wire erosion, wire burning, and spark EDM.

Wire EDM is an electrothermal production process that involves using focused electrical energy to generate heat to machine materials. The process uses a thin metal wire electrode to create electrical discharge between it and the workpiece. Deionized water conducts electricity and enables the electrode to cut through the metal while preventing corrosion. This method is also known as wire erosion, wire burning, and spark EDM.

What Is Conventional EDM?

Conventional EDM involves machining an electrode into a specific shape. The shaped electrode is then used to machine workpieces. Conventional EDM is also known as die sinking, sinker EDM, cavity-type EDM, and volume EDM. Because it uses distinctively shaped electrodes, this process is commonly used for die- and mold-making. Conventional EDM is also ideal for low-volume production and prototyping in a wide range of industries, due to its ability to produce accurate, complex profiles and parts.

How Does Wire EDM Work?

The wire EDM process produces electrical discharge between the workpiece undergoing machining and the wire electrode. This discharge, in the form of a spark, moves between the workpiece and machining media, gradually removing material from the workpiece. Wire EDM allows for the efficient machining of complex components with tight tolerances, particularly for metals that are hard and electrically conductive.

The wire EDM process produces electrical discharge between the workpiece undergoing machining and the wire electrode. This discharge, in the form of a spark, moves between the workpiece and machining media, gradually removing material from the workpiece. Wire EDM allows for the efficient machining of complex components with tight tolerances, particularly for metals that are hard and electrically conductive.

To prevent shorting out during the machining process, wire EDM also uses a dielectric or non-conductive fluid media. This media removes waste material and enables the EDM process to continue.

Industries Served

Many industries use the wire EDM process for machining various parts and components. Some of these sectors include:

- Aerospace

- Automotive

- Electronics

- Semiconductor

The aerospace industry often relies on wire EDM and other machining processes to fabricate products with tight tolerances and that help airplanes, rockets, and other vehicles withstand harsh environments. As a result, the aerospace industry may use wire EDM to help fabricate everything from turbine blades and rotor discs to stator parts and compressor wheels.

Applications of Wire EDM

Wire EDM works with many applications, especially metal tool manufacturing. Because of its ability to machine hard workpieces, wire EDM is often used to create extrusion dies, molds, carbide tools, microtooling, and press tools. Wire EDM is also ideal for precise drilling, creating holes smaller than 0.1 mm in components such as pneumatic brakes. The wire EDM process is suitable for prototypes, mass production runs, and other projects requiring low residual stress.

Benefits of Wire EDM vs. Conventional EDM

In conventional EDM, electrodes tend to erode and must be replaced regularly when worn out. Because electrodes must be pre-machined into special shapes, this can add time to the overall process. In contrast, wire EDM can begin as soon as the electrode is in place and does not require extra time or spending on pre-machining. This makes it suitable for time-sensitive projects and shapes not possible to produce with conventional EDM’s matching electrodes.

Wire EDM is a reliable and robust machining method that is user-friendly for operators. These are just some of the benefits of wire EDM compared to conventional EDM:

- Speed

- Efficiency

- Ease of production

- Low labor and operating costs

- Low maintenance

Wire EDM Services From OPM – Precision Manufacturing

Wire EDM can meet the needs of many projects that require efficient and precise machining, but it’s important to find the right provider to get the best results from these services. If you require wire EDM or other machining processes for your application, OPM Inc. has the resources and expertise to meet your needs. You’ll benefit from reliable wire EDM services along with logistic and engineering support, real-time traceability, customization options, and a more efficient supply chain.

Regardless of the complexity of your application and individual requirements, we’ll meet them with the most appropriate EDM solution. In addition to EDM, we can employ other services to fulfill your project needs, including CNC machining, heat treating, material analysis, cold drawing, tube rolling, and inspection.

Want to learn more about our services and get started on a custom solution for your application? Contact us today.